Bambu Lab H2D AMS HT Bundle

Bambu Lab H2D revolutionizes personal manufacturing with dual-nozzle printing, laser engraving/cutting, and digital plotting in one desktop unit. Featuring Bambu Lab's largest 350×320×325 mm build volume and all-metal hotends reaching 350°C, it handles advanced materials including carbon fiber composites with 65°C active chamber heating. Ultra-high-speed performance delivers 1000 mm/s toolhead speed with 20,000 mm/s² acceleration via CoreXY architecture and hardened steel dual nozzles for exceptional precision. AI-powered monitoring through 4 computer vision cameras and 36 sensors ensures flawless results, while AMS 2 Pro and AMS HT compatibility enables up to 16-color printing with integrated filament drying.

Key Features

-

All-in-One Manufacturing Hub – Combines 3D printing, laser engraving/cutting, and digital plotting for complete creative workflow

-

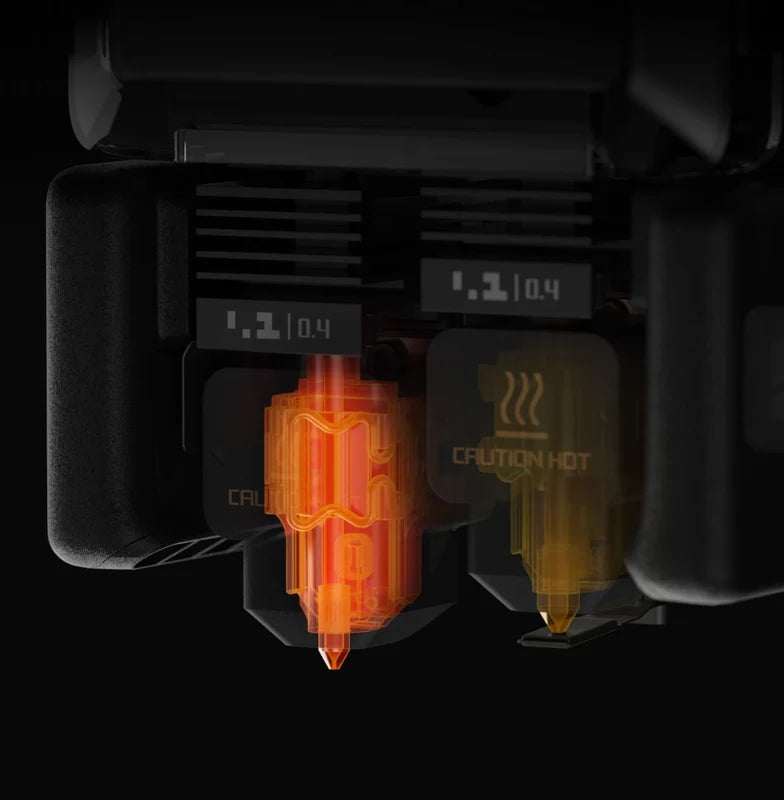

Advanced Dual-Nozzle System – Hardened steel nozzles with 350°C capability for multi-material carbon fiber printing

-

Ultra-High-Speed CoreXY – 1000 mm/s toolhead speed with 20,000 mm/s² acceleration and 50μm motion accuracy

-

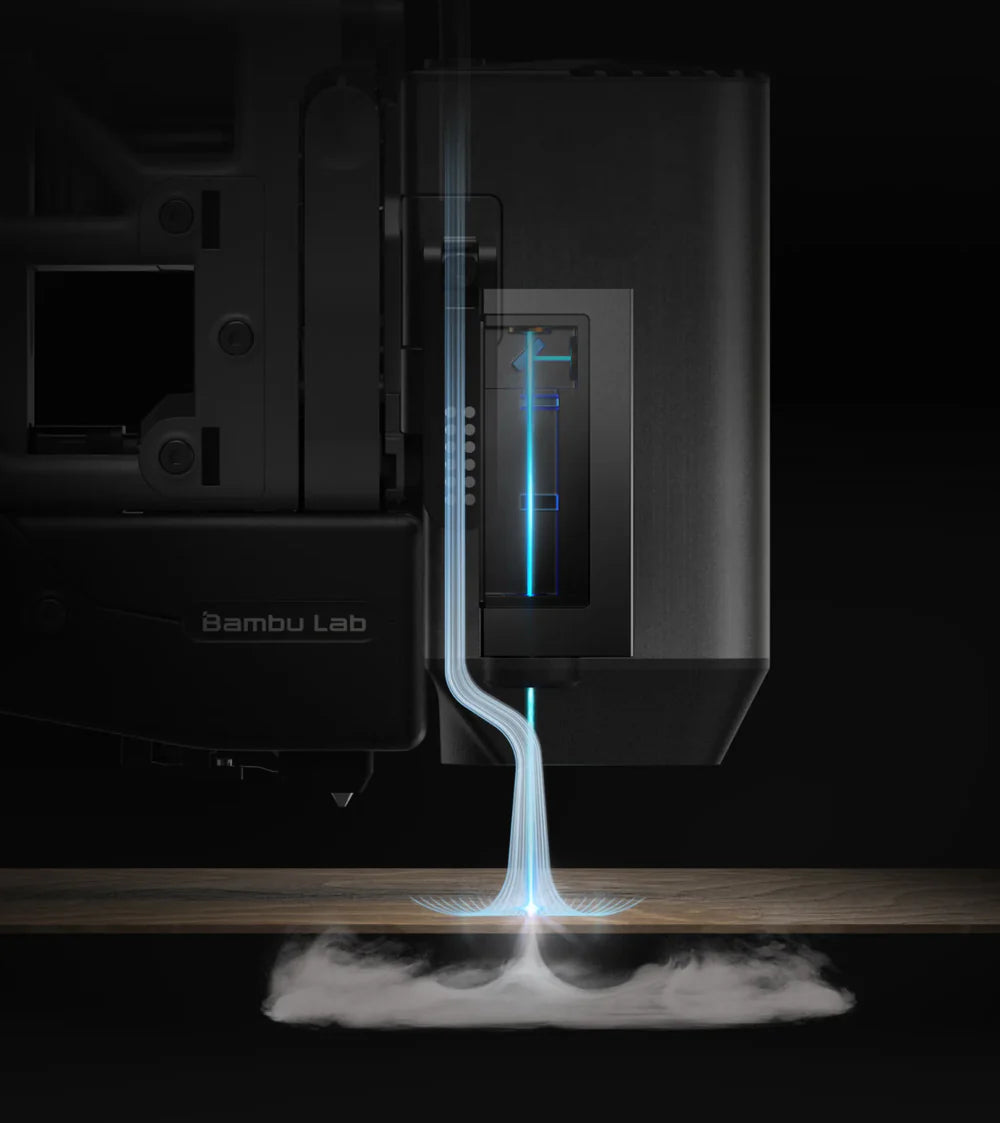

Professional Laser Capabilities – 10W/40W laser modules cut up to 15mm plywood with air assist and rotary attachment

-

Comprehensive AI Monitoring – 4 vision cameras, 36 sensors, macro lens nozzle camera for failure detection

-

Advanced Material Management – AMS 2 Pro/AMS HT with integrated filament drying and 15-sensor path monitoring

-

Maximum Build Volume – Industry-leading 350×320×325 mm workspace with 65°C active chamber heating

Unleash The Full Potential of High-Performance Materials

Equipped with 65°C active chamber heating and a high-temperature hotend reaching up to 350°C, the H2D delivers precise closed-loop temperature control. This advanced system effectively eliminates warping and deformation in high-performance materials, ensuring superior layer bonding and maximizing their full potential.

Air Assist

Improve surface quality by directing high-speed air to cool the laser path, ensuring cleaner and more precise results.

Full -Auto Calibration

A single tap initiates automated laser focus verification and material measurement, eliminating manual adjustments.

SOTA Filament Monitoring

Unlike legacy systems with single filament run-out detectors, the H2D features comprehensive material flow monitoring. Throughout the AMS-to-nozzle path, 15 strategic sensors form an intelligent network, continuously tracking five key parameters: feeding velocity, tension, filament tip location, extruder thermal environment, and dynamic extrusion pressure. This establishes an industry-leading filament behavior control system.

| Item | H2D AMS Combo | H2D Laser Full Combo | H2D |

|---|---|---|---|

| Bambu Lab H2D | ✓ | - | ✓ |

| Bambu Lab H2D Laser Edition | - | ✓ | - |

| Textured PEI Build Plate | ✓ | ✓ | ✓ |

| Spool Holder | ✓ | ✓ | ✓ |

| Accessory Box | ✓ | ✓ | ✓ |

| AMS 2 Pro | ✓ | ✓ | - |

| 10W Laser Module | - | Depending on selected combo | - |

| 40W Laser Module | - | Depending on selected combo | - |

| Cutting Module (with pen holder) | - | ✓ | - |

| Laser Platform | - | ✓ | - |

| Cutting Platform | - | ✓ | - |

| Safety Key | ✓ | ✓ | ✓ |

| Ventilation Pipe | - | ✓ | - |

| Laser & Cutting Materials | - | ✓ | - |

| Emergeny Stop Button | - | - | - |

Product specifications

H2D Tech Specs

| Printing Technology | Fused Deposition Modeling |

| Build Volume | Single Nozzle – 325 × 320 × 325 mmDual Nozzle – 300 × 320 × 325 mmTotal Volume – 350 × 320 × 325 mm |

| Body | Aluminum, Steel, Plastic, and Glass |

| Weight | 31 kg |

| Dimensions | 492 × 514 × 626 mm |

| Toolhead & Hotend | All-Metal Hotend with Hardened Steel Extruder & Nozzle |

| Max Nozzle Temp | 350 °C |

| Supported Nozzle Sizes | 0.2 mm – 0.8 mm (default 0.4 mm) |

| Filament Diameter | 1.75 mm |

| Build Plate | Textured & Smooth PEI Plates |

| Max Bed Temp | 120 °C |

| Active Chamber Heating | Up to 65 °C |

| Air Purification | G3 Pre-filter, H12 HEPA, and Granulated Carbon Filter |

| Max Speed | 1000 mm/s |

| Acceleration | 20,000 mm/s² |

| Max Flow | 40 mm³/s (Standard Hotend) 65 mm³/s (High-Flow Hotend) |

| Supported Materials | PLA, PETG, TPU, PVA, ABS, ASA, PC, PA, PET, and carbon/glass fiber-reinforced materials (PLA-CF, PETG-GF, PPS-CF, etc.) |

| Laser Power | 10 W or 40 W Blue Light |

| Engraving Speed | up to 1000 mm/s |

| Supported Materials | Wood, Leather, Metal Sheet, Acrylic, Stone, etc. |