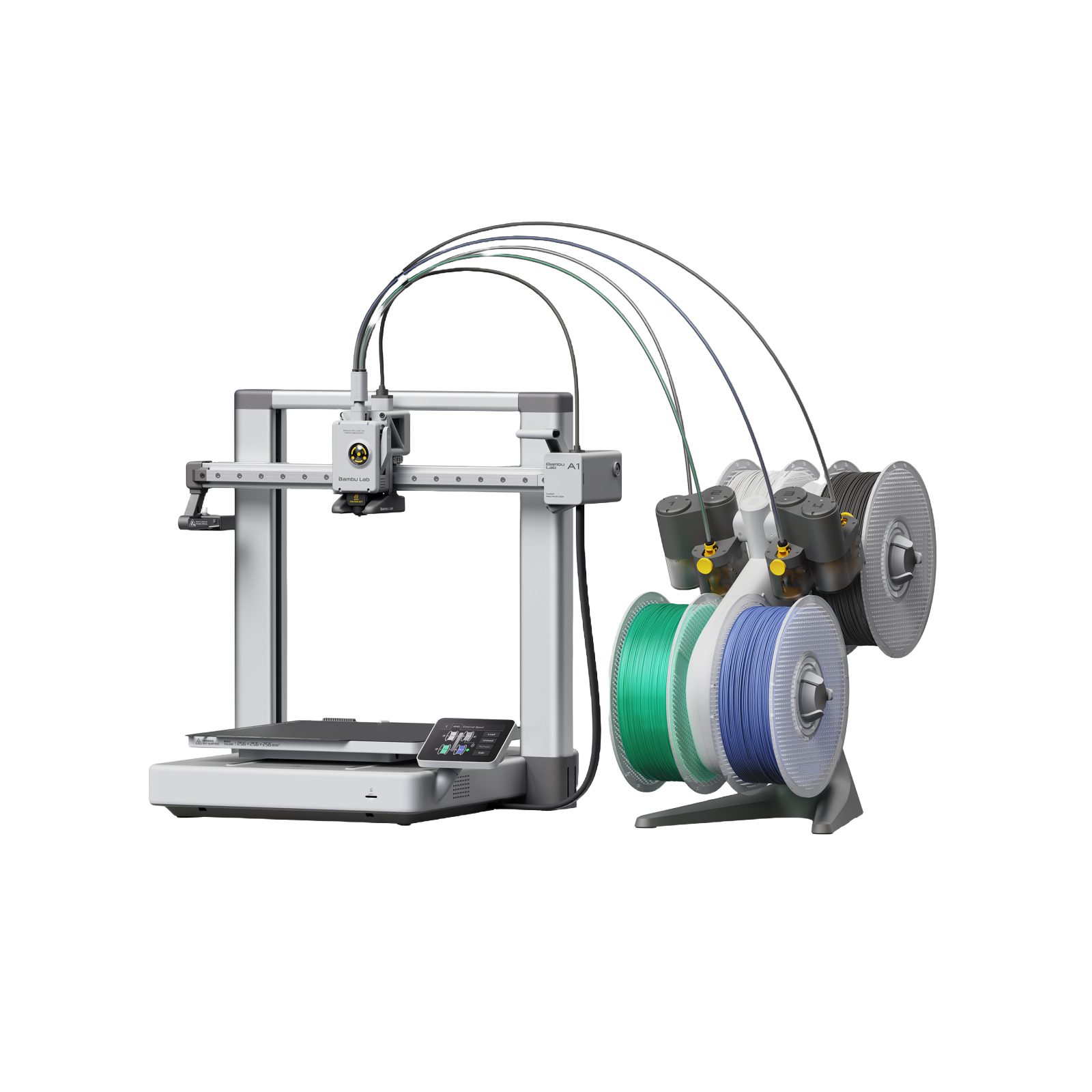

Bambu Lab A1 Series

Bambu Lab A1 3D printer delivers bed-slinger performance with 500 mm/s printing speeds and 10,000 mm/s² acceleration for exceptional results. Featuring a generous 256×256×256 mm build volume and all-metal hotend reaching 300°C, it supports PLA, PETG, TPU, and PVA with thermal precision. Full auto-calibration handles Z-offset, bed leveling, and vibration compensation for every print job without manual adjustment. The stainless steel nozzle and Active Motor Noise Cancelling create whisper-quiet operation under 48 dB in Silent Mode. Direct drive extruder with hardened steel gears ensures consistent filament feeding and reliable performance.

Key Features

-

Full Auto-Calibration System – Automatic Z-offset, bed leveling, and vibration compensation for every print job

-

High-Speed Bed-Slinger Design – 500 mm/s printing with 10,000 mm/s² acceleration and full-metal rails

-

Multi-Color AMS Lite Ready – Compatible with 4-color printing system for creative projects

-

All-Metal Construction – 300°C hotend with stainless steel nozzle and hardened steel extruder gears

-

Silent Operation – Active Motor Noise Cancelling reduces noise under 48 dB in Silent Mode

-

Direct Drive Precision – Hardened steel gears with filament cutter for reliable material handling

-

Comprehensive Sensor Suite – Filament run-out, tangle detection, odometry, and 1080P monitoring camera

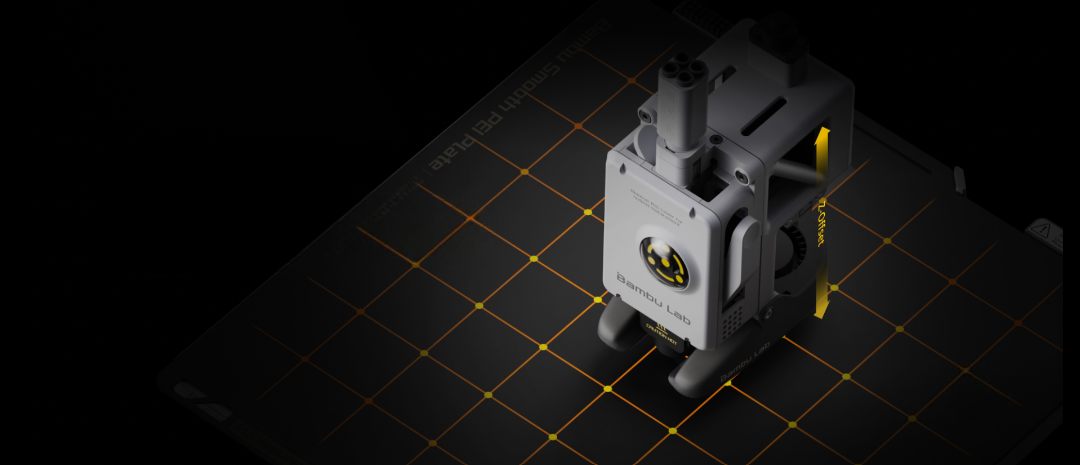

Full Auto Calibration

The A1 mini handles various calibrations all by itself. It meticulously calibrates the Z-offset, bed-level, vibration resonance and nozzle pressure for EVERY print job, automatically.

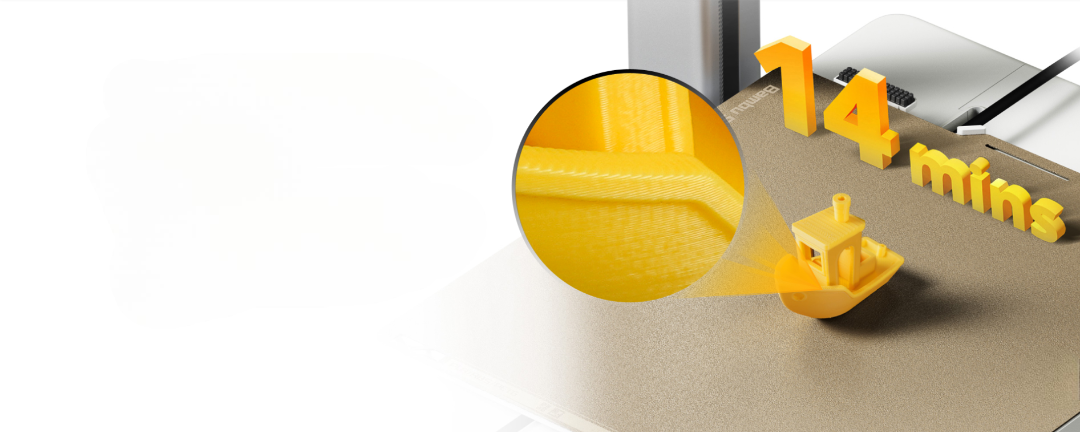

Bed Slinger, with CoreXY Speed And Quality(High-Speed Precision)

Full-metal Rails, rigid frame, nozzle pressure sensor, accelerometers, powerful MCU, and above all, an advanced motion control system that utilizes these features to print a 14-minute benchy with quality and following all the speed benchy rules straight out of the box without using specialized filaments.

Active Flow Rate Compensation

Unlike the linear and Newtonian movement of the XYZ axes, the viscous flow of the melted plastic is non-Newtonian. The amount of plastic pushed into the hot end by the extruder doesn't necessarily equate to the amount flowing out of the nozzle, especially at high accelerations. This discrepancy can lead to swollen corners and artifacts where the speed changes. This is where active flow rate compensation comes into play. It helps to predict and adjust the flow of the molten plastic, facilitating more accurate extrusion. Previously, we used to print straight lines with acceleration and measure the line's width to calibrate the parameters for compensation - a process that was time-consuming and wasted space on the build plate. In the A1, we employ a novel method to measure the nozzle pressure, allowing us to directly obtain the necessary parameters before each print, saving time and preserving build plate space.

Product specifications

A1 Tech Specs

| Build Volume(W*D*H) | 256*256*256 mm³ |

| Hot End | All-Metal |

| Nozzle | Stainless Steel |

| Max Hot End Temperature | 300 °C |

| Nozzle Diameter | 0.4 mm (Included) 0.2 mm, 0.6 mm, 0.8 mm |

| Build Plate | Bambu Textured PEI Plate (Included) Bambu Smooth PEI Plate Bambu Dual-Texture PEI Plate Bambu High Temperature Plate (Smooth PEI) Bambu Cool Plate |

| Max Build Plate Temperature | 100°C |

| Max Speed of Tool Head | 500mm/s |

| Max Acceleration of Tool Head | 10000mm/s² |

| PLA, PETG, TPU, PVA | Ideal |

| ABS, ASA, PC, PA, PET,Carbon/Glass Fiber Reinforced Polymer | Not Recommended |

| Chamber Monitoring Camera | Low Framerate Camera (Up to 1080P)Timelapse Supported |

| Filament Run Out Sensor | Yes |

| Filament Odometry | Yes |

| Power Loss Recover | Yes |

| Filament Tangle Sensor | Yes |

| Physical Dimensions | A1 : 385*410*430 mm³ , Package size : 596*536*325 mm³ , Net weight 8.3 kg , Gross weight 13 kg A1 Combo : Package size 560*540*430 mm³ , Gross weight (AMS lite included) 13.5 kg |