PioCreat G12

PioCreat G12

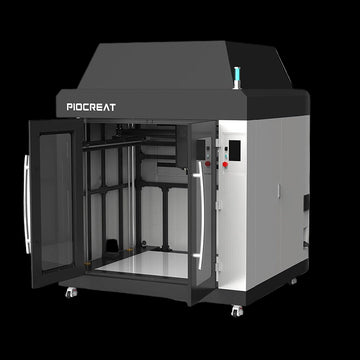

PioCreat G12 delivers industrial-scale FGF manufacturing with 1200×1000×1000 mm build volume and 100 mm/s printing speeds for large-format production. Featuring a screw extrusion system with 450°C nozzle capability and 60°C heated chamber, it processes thermoplastic pellets including PA-CF, PC-CF, ABS, PETG, TPU, and recycled materials directly from a 20-liter hopper. Automatic multi-point leveling with BLTouch sensor and intelligent pellet runout detection ensure 99% success rates for uninterrupted batch production. Servo motor precision control and rapid 130°C bed heating within 5-8 minutes optimize workflow for industrial applications including molds, tooling, and full-scale prototypes.

Key Features

-

Massive Industrial Build Volume – 1200×1000×1000 mm workspace ideal for large molds, tooling, furniture, and architectural models

-

High-Temperature Screw Extrusion – 450°C nozzle with flow rates up to 5 kg/hour for rapid large-format production

-

Advanced Material Flexibility – Processes pellets, recycled plastics, fiber-reinforced composites reducing costs by 60%

-

Professional Automation Suite – Multi-point auto-leveling, pellet runout detection, power-loss recovery, and chamber temperature control

-

Industrial-Grade Performance – 60°C heated chamber with servo motor control ensures injection-molding quality results

-

Rapid Setup Technology – 130°C rapid heating bed in 5-8 minutes with intelligent laser ranging for shortened preparation

-

Complete Connectivity – USB/SD card transfer, touchscreen interface, and emergency safety systems for production environments

Bring Sculptures to Life with the G12 by Piocreate

Unlock unmatched detail and precision in every curve. The G12's high-speed resin printing and large build volume make it the perfect choice for artists, designers, and studios looking to create lifelike sculptures with incredible surface quality. From miniature figurines to bold art pieces — sculpt with confidence, sculpt with Piocreate.

Precision Tube Printing with the G12 by Piocreate

Designed for demanding geometries, the G12 delivers flawless tube structures with smooth interiors and sharp detail. Whether you're prototyping functional parts or printing medical, industrial, or architectural models, the G12 ensures dimensional accuracy and excellent surface finish — every time.

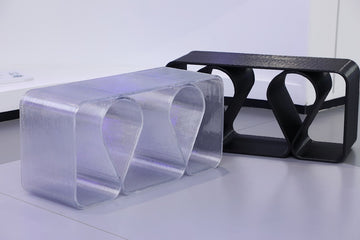

Innovative Furniture Prototyping

Transform your design ideas into tangible prototypes with the G12’s large-format resin printing. Ideal for intricate furniture models and functional components, the G12 offers high-speed precision, smooth surfaces, and structural integrity — helping designers and makers visualize, iterate, and impress.

Advanced Manufacturing Applications

Built for industrial performance, the G12 empowers manufacturers to rapidly produce functional prototypes, tooling components, and end-use parts with high accuracy and repeatability. Its large build volume and fast resin printing technology make it ideal for streamlining workflows and accelerating product development.

Elevate Carving Art

Capture every fine line and intricate texture with precision. The G12 is perfect for carving-inspired art, delivering ultra-high-resolution prints that preserve the essence of hand-carved detail. From decorative patterns to artistic reliefs, bring your creative vision to life with unmatched clarity and speed.

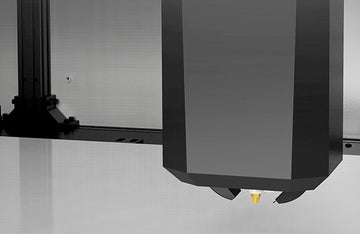

Nozzle Temperature Up to 450℃

With a nozzle temperature reaching up to 450°C and a bed temperature of ≤130°C, the G12 Pellet 3D Printer’s nozzle is designed to handle high-temperature materials. This enables the printer to work with a wide array of thermoplastics and composite materials, including PLA, PETG, ABS, TPU, and composite materials, broadening the horizon for creating durable, complex parts with ease.

High Flow Screw Extrusion

The G12 features a pioneering screw extrusion system, revolutionizing large-format 3D printing with its powerful, even extrusion force for uniform material flow and adhesion. It offers versatile slice thicknesses (0.2-1.5mm) and nozzle sizes (0.6-4mm), enabling both fine details and high flow rates (up to 3kg/hr), enhancing print quality and flexibility.

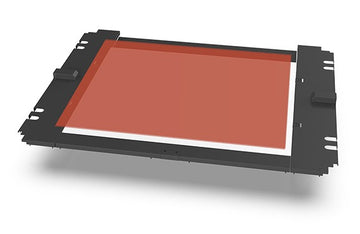

Rapid Heating of Hot Bed Up to 130℃

Accelerate your production timeline with the rapid-heating bed of the G12, capable of reaching temperatures up to 130°C. This feature greatly reduces the wait time for the printing set-up, enabling faster turnaround for projects, and ensuring optimal bed adhesion for large prints.

Powerful Servo Motor

Precision is paramount when it comes to large-scale printing, and the G12 does not compromise. The integration of a customized, powerful servo motor translates to superior motion control and unparalleled printing accuracy. Whether you are printing intricate patterns, molds, tooling, or full-scale prototypes, the G12 delivers quality prints with a level of detail that sets it apart from the competition.