Fiberon PETG-ESD

Fiberon PETG-ESD

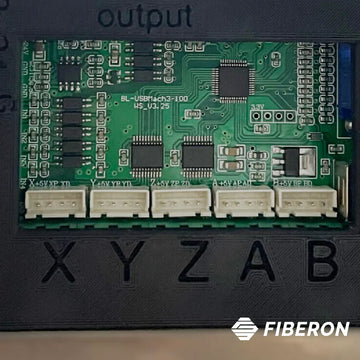

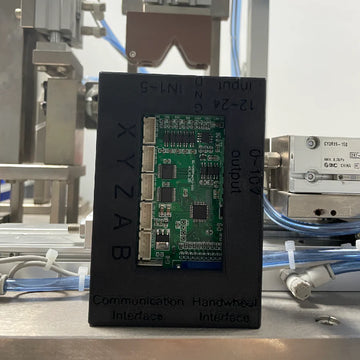

Experience professional electronics protection with Fiberon PETG-ESD filament, delivering ESD safe electronics housing printing with superior anti-static composite performance. This carbon nanotube enhanced filament features ultra-low surface resistivity (1.6±0.3)E+7Ω, 76°C HDT, and moisture-insensitive reliability for consistent electronic component protection. Engineered for electronics assembly fixture material applications at 250-290°C, offering dimensional stability and excellent layer adhesion without heated chambers. Trust this professional electrostatic dissipative printing material for critical electronics manufacturing, automotive sensors, and aerospace applications requiring precision static discharge protection.

Key Features

-

ESD Safe Electronics Protection ultra-low surface resistivity for sensitive component safety

-

Carbon Nanotube Enhanced superior electrostatic discharge dissipation performance guaranteed

-

Heat Resistant Engineering 76°C HDT for demanding electronics applications reliability

-

Anti-Static Composite Material consistent ESD properties 250-290°C printing range

-

Electronics Assembly Ready no annealing required user-friendly manufacturing process

-

Professional Grade Performance dimensional stable moisture-insensitive electronics industry proven

Fiberon PETG-ESD is a carbon nanotube-reinforced PETG filament offering electrostatic discharge (ESD) safety with a density of 1.24 g/cm³ and heat deflection temperature of 76°C at 0.45 MPa. The material exhibits exceptional toughness with Young's modulus of 1983 MPa in the X-Y direction and 36.1 MPa tensile strength, while maintaining low moisture absorption of 0.41% equilibrium. Its surface resistivity ranges from 10^4 to 10^7 ohms depending on printing temperature, providing reliable ESD protection for sensitive electronics.

Fiberon PETG-ESD excels in electronics manufacturing, automotive applications, and jigs & fixtures where ESD protection is critical for handling sensitive components. It prints reliably on standard FDM printers with nozzle temperatures of 250-290°C and bed temperatures of 70-80°C, requiring no heated chamber or cooling fan, making it compatible with entry-level to industrial-grade systems. Both electronics professionals and experienced makers can achieve printing speeds up to 500mm/s while producing anti-static housings, assembly tools, and functional prototypes.

Users benefit from PETG-ESD's reliable ESD protection, improved impact resistance over standard PETG, and excellent dimensional accuracy without warping or layer delamination. The carbon nanotube reinforcement provides consistent electrostatic dissipation while maintaining the ease of printing characteristic of PETG materials. However, the abrasive carbon nanotubes require hardened steel nozzles to prevent wear, and drying at 65°C for 3 hours before printing is recommended for optimal performance.