eSUN PLA-Matte

eSUN PLA-Matte

eSUN PLA-Matte filament delivers professional matte finishes with exceptional print reliability. Engineered for high-speed printing and environmental sustainability, it features low density, high rigidity, and PC-like strength without odors or warping. Supports peel off effortlessly and prints large models smoothly.

Key Features

-

Environmental friendly and cost-effective

-

High-speed printing for rapid prototyping

-

Excellent printability with no clogging or odors

-

Support structures peel off easily for clean surfaces

-

Not easy to break - smooth long-term printing

-

Matte surface effect hides layer lines for refined textures

Matte Surface - Delicate Without Layer Lines & Good Printing Effect

eSun PLA-Matte produces prints with an elegant matte finish that effectively conceals layer lines, creating a smooth and refined appearance. The specialized matte additive gives prints a professional, non-reflective surface that enhances visual appeal and provides a premium tactile experience. Processing at standard temperatures of 190-230°C, this filament delivers consistent results with excellent surface quality, making it ideal for decorative items, prototypes, and display models that require a sophisticated finish.

PLA Toughened - Higher Toughness & Hard to Break

eSun PLA-Matte offers significantly enhanced durability compared to standard PLA, with improved impact resistance and flexibility that reduces breakage during handling and use. The material demonstrates superior elongation properties of over 50% and enhanced tensile strength, making both the filament and finished prints more resilient. This improved toughness ensures reliable performance during extended printing sessions and produces parts that can withstand normal handling and minor impacts without failure.

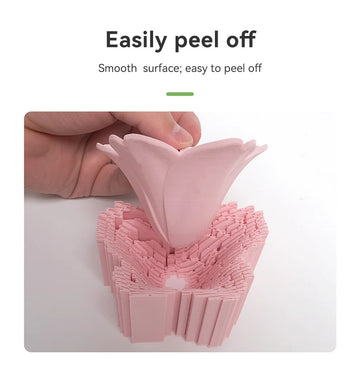

Easy to Peel Off - Smooth Surface & Easy Removal

eSun PLA-Matte features excellent support removal characteristics, allowing support structures to detach cleanly and effortlessly from printed models. The smooth interface between supports and the main print ensures clean separation without surface damage or the need for additional tools. This streamlined post-processing capability reduces finishing time and makes the filament particularly suitable for complex geometries that require extensive support structures.