Bambu Lab X1E Combo

Bambu Lab X1E Combo

Bambu Lab X1E delivers professional engineering-grade performance with 500 mm/s printing speeds and 20,000 mm/s² acceleration for industrial applications. Featuring a 256×256×256 mm build volume and all-metal hotend reaching 320°C, it handles advanced engineering materials including PPA-CF/GF, PPS, PPS-CF/GF with active 60°C chamber heating. Dual auto bed leveling with 7μm lidar resolution and AI-powered monitoring ensures consistent results, while heavy-duty air filtration with G3 pre-filter and H12 HEPA filter provides safe operation with carbon fiber and glass fiber materials. AMS, AMS 2 Pro, and AMS HT compatibility supports up to 16-color printing with WPA2-Enterprise security and LAN-only mode for secure enterprise environments.

Key Features

-

High-Temperature Engineering Materials – 320°C hotend enables PPA-CF/GF, PPS, PPS-CF/GF for superior dimensional stability

-

Active Chamber Heating – 60°C controlled environment minimizes warping and enhances layer adhesion for technical parts

-

Enterprise Security Features – WPA2-Enterprise Wi-Fi, LAN-only mode, physical network kill switches for secure environments

-

Heavy-Duty Air Filtration – G3 pre-filter and H12 HEPA filter with activated carbon for safe carbon fiber printing

-

Ultra-High-Speed CoreXY – 500 mm/s printing with 20,000 mm/s² acceleration using carbon fiber rails

-

Professional Multi-Material System – Compatible with up to 4 AMS units for 16-filament printing with automatic reloading

-

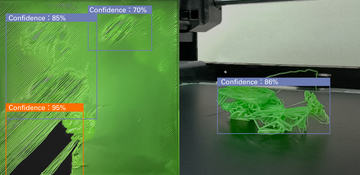

Advanced AI Monitoring – Lidar and computer vision detect failures, first-layer defects, and spaghetti formations automatically

Shipping cost is based on weight. Just add products to your cart and use the Shipping Calculator to see the shipping price.

We want you to be 100% satisfied with your purchase. Items can be returned or exchanged within 30 days of delivery.

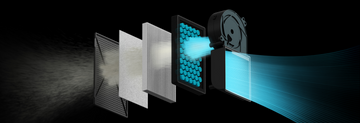

Effectively Filter Particulates And VOCs Generated by 3D Printing

Achieve effective air filtration for 3D printers with Bambu Lab’s advanced multi-stage filter system. This solution features a G3 pre-filter, an H12 HEPA filter, and high-grade coconut shell activated carbon to filter particulates and volatile organic compounds (VOCs) produced during 3D printing. The system reduces odors and airborne contaminants, providing a cleaner workspace even in environments with limited ventilation.

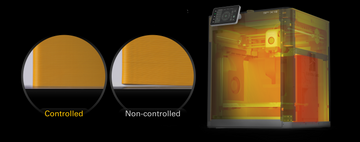

Reduce Warping, Improve Layer Bonding

Minimize warping and enhance layer adhesion with the Bambu Lab X1E’s actively heated chamber. This 3D printer precisely controls chamber temperatures up to 60°C (140°F), delivering optimal conditions for materials prone to warping such as ABS and polycarbonate (PC). Consistent thermal regulation supports superior print quality and improved bonding between layers, making the X1E a reliable solution for demanding printing applications.

More Heat For Higher Temperature Materials

The Bambu Lab X1E features a high-temperature nozzle, allowing reliable 3D printing with advanced materials like PPA-CF, PPA-GF, PPS, and PPS-CF. These materials offer greater heat resistance, dimensional stability, and mechanical strength, making the X1E ideal for professional and industrial applications.

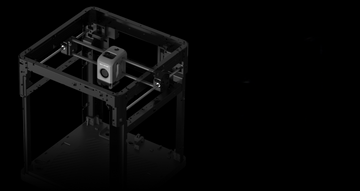

Super Fast And Rigid Structure For Continuous High Speed Printing

The Bambu Lab X1E features a rigid CoreXY motion structure enhanced with carbon-fiber rods, minimizing moving mass for superior speed and stability. With toolhead acceleration up to 20,000 mm/s², the X1E sustains high travel speeds of 500 mm/s, enabling continuous high-speed printing and significantly reducing print times.

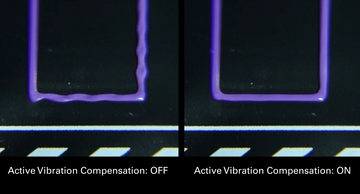

Stable & Quality Prints Even At Higher Speeds

The Bambu Lab X1E ensures stable, high-quality prints even at elevated speeds through active compensation of XY-axis vibrations and extrusion inconsistencies. Fully automatic measurement and adjustment systems maintain smooth surface quality and print accuracy, eliminating manual calibration.

Reduce Filament Wastage And Machine Downtime

Minimize filament waste and reduce machine downtime with the Bambu Lab X1E’s advanced AI monitoring. Equipped with Lidar and computer vision, the X1E automatically detects first-layer issues and spaghetti failures, pausing the print to prevent material loss and print failures.

Supports Auto Filament Reload and Enables Multi-Material Printing with Support Material for Improved Surface Quality

The Bambu Lab X1E supports automatic filament reloading and advanced multi-material printing. By connecting up to four Bambu AMS units in parallel, the X1E can print with as many as 16 different filament spools. This enables efficient use of dedicated support materials for better surface finishes and seamless multi-color or multi-material prints. The AMS automatically reloads filaments, ensuring minimal material waste and uninterrupted printing.