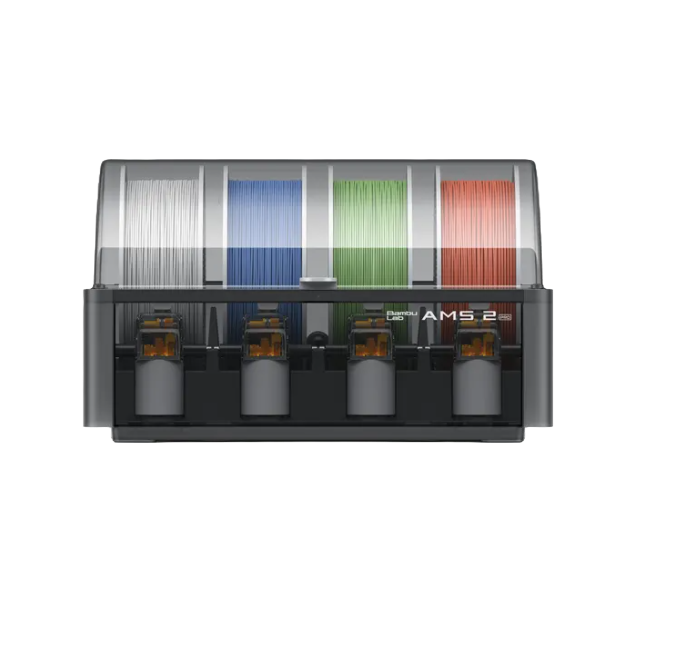

Bambu Lab AMS 2 Pro - Automatic Material System

Bambu Lab AMS 2 Pro delivers revolutionary multi-material printing with 24-filament capacity through serial connectivity with 4 AMS 2 Pro + 8 AMS HT units and 60% faster feeding speeds via brushless servo motor technology. Featuring 65°C active drying with electromagnetic air venting and auto-rotate functionality, it maintains optimal filament conditions with airtight sealed storage and real-time humidity monitoring. RFID sync technology automatically configures drying settings for Bambu official filaments, while tool-free filament tube access and ceramic inlet design with Vickers hardness 1200 enhance durability and maintenance. Compatible with X1/P1 series printers with 24V 4A power requirement for drying functions and upcoming A1/A1 Mini support via Q3 2025 OTA update.

Key Features

-

Advanced 65°C Drying System – Electromagnetic air venting with auto-rotate spools ensures even moisture removal and airtight storage

-

Ultra-Fast Brushless Servo Motor – 60% faster feeding speed saves 10 minutes per 100 filament changes for enhanced efficiency

-

24-Filament Expansion Capability – Serial connectivity supports up to 4 AMS 2 Pro + 8 AMS HT units for complex multi-material projects

-

Intelligent RFID Recognition – Automatic filament identification and optimal drying settings for Bambu official materials

-

Professional Material Compatibility – Supports PLA, PETG, ABS, ASA, PA, PC, PVA (dried), BVOH (dried), Bambu CF composites

-

Enhanced Maintenance Design – Tool-free filament tube access and ceramic inlets with 1200 Vickers hardness for durability

-

Complete Humidity Management – Real-time temperature and humidity detection with sealed storage and active moisture discharge